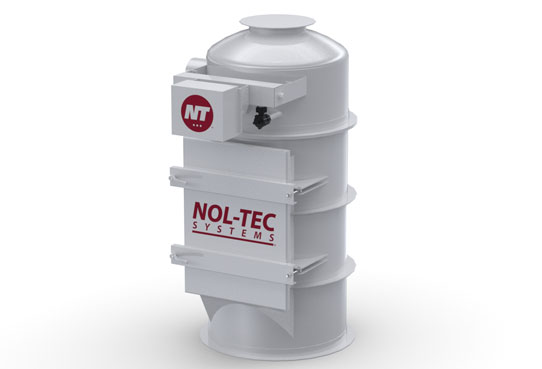

Vacuum Filter/ Receiver

Nol-Tec vacuum filter receivers effectively separate product from the motive air in a vacuum conveying system.

Specifications

To learn more about our Vacuum/Filter Receiver, please review the specifications below. If you have additional questions, please feel free to hit the get in touch button below and someone from our team will follow-up promptly.

Standard Features:

- Heavy gauge continuous welded construction

- Reinforced housing

- Reverse pulse jet cleaning

- Bottom grate

- Cartridge or bag filter media

- Magnehelic gauge

- Hopper bottom

- Quick-release bag clamps

- Access door

- Vacuum design 17” Hg

OPTIONAL FEATURES:

- Stainless steel construction

- Hazardous location design

- High-temperature design

- Variety of filter media materials available

- Additional access doors

- Hopper aeration

- High vacuum design to 30” Hg

SPECIFICATIONS:

- Compressed air: Clean and dry at 80 PSIG minimum

- Temperature: Polyester bags 250° F, Polyester cartridge with urethane ends 225° F

- Electrical: Designed to meet customers specification

Resources

We have a vast knowledge base of research and hands-on experience that covers topics from market trends to complex dry bulk material handling challenges.

Product Literature

How can we help?

Maybe you need a new system, an upgrade to an existing system, or a retrofit. Regardless of size, industry, or material, we are here to help you get your project and product moving.

Get in touch