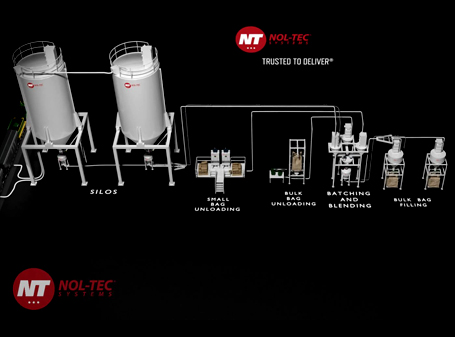

Nol-Tec Process Highlights

Click to play the video on the right for an overview of our process.

Learn MoreHow to Size a Dense Phase PNEUMATIC CONVEYING System

Manually sizing a dense phase pneumatic conveying system is often considered a “black art” — a type of tribal knowledge learned and passed down over time by a handful of manufacturers.

Learn More

Lime Kiln MACT Compliance Technology

Dry sorbent injection (DSI) removes HCl and other acid gases using a powdered alkali sorbent injected into the exhaust gas ductwork where it then reacts with the HCl in the exhaust stream.

Learn More

Battery Production Pneumatic Blender

If you have a battery production facility that requires a blending of dry materials, then you should look no further than Nol-Tec Systems industry leading blending technology.

Learn More

Five design considerations to ensure moisture does not degrade your battery

A well-engineered pneumatic conveying system provides the best solution to control moisture and ensures a safer and more stable manufactured battery. In this article we discuss five considerations that ensure a good system design.

Learn More

Keys to Successful Pneumatic Conveying

Download our Nol-Tec sponsored eBook, “Keys to Successful Pneumatic Conveying” with a featured article by Iain McNerlin and Brandon Lofquist.

Download PDF

Answers to Eight Common Questions about Pneumatic Conveying

While pneumatic conveying is a common method of transferring powders, granules, and other dry bulk materials, understanding this conveying technology can be a challenge. This article addresses pneumatic conveying questions frequently asked by people in dry bulk materials processing and handling plants.

Learn More

Saving Time, Labor, and Money with Pneumatic Batch Blending

With a pneumatic blender, you can mix batches of dry bulk materials in the conical hopper of a storage vessel or dense phase pneumatic conveying transporter rather than in a mechanical mixer, yielding real savings in time, labor, and capital equipment costs. After explaining how the pneumatic blender works, this article describes its applications and benefits and details how testing can help you select the blender for your application.

LEARN MORE

Four Basic Details to Consider with Dense Phase Pneumatic Conveying

Dense phase pneumatic conveying offers many advantages for bulk material handling. It is typically, the first choice for moving abrasive materials, and has been used successfully to convey all kinds of agglomerated, friable, heavy, or blended bulk materials. However, to experience these advantages, many aspects of conveying system design need to be considered. The details can make or break a successful system installation.

Learn More

Common Differences Between Dense Phase Pressure Conveying and Dense Phase Vacuum Conveying

Dense phase pneumatic conveying is a method for moving difficult, abrasive, mixed batch, or friable materials at a low speed. The materials move along an enclosed pipe, in slug form using small amounts of gas at a low velocity and high pressure. This article introduces the two most common types of dense phase conveying – pressure and vacuum.

LEARN MORE

Common Differences Between Dilute Phase Pressure Conveying and Dilute Phase Vacuum Conveying

Dilute phase pneumatic conveying is a method of moving non-abrasive, non-fragile materials that have a low bulk density. The materials move along an enclosed pipe, in slug form using small amounts of gas at a high velocity and low pressure. This article introduces the two most common types of dilute phase conveying – pressure and vacuum.

Learn More

Learn How to Improve Dense Phase Pneumatic Conveying System Performance, Efficiency, and Reliability with the Use of Air Injector Technology

Dense phase pneumatic conveying is a method for moving difficult, abrasive, mixed batch, or friable materials at a low velocity. The materials move along an enclosed pipe, in slug form using small amounts of gas at a low velocity and high pressure. Learn how the addition of air injector technology that is strategically placed throughout the system improves system performance, efficiency, and reliability.

Learn More

Why the Nol-Tec Pneumatic Blender Is Unique Compared to Other Pneumatic Blender Designs

The pneumatic blending cone provided by Nol-Tec is usually mounted into the bottom of the discharge cone of a vertical cylindrical vessel. It is designed to use pulses of compressed air, or other gas to blend various powdered or granular bulk solid materials into a homogenized mixture. This article outlines the design features incorporated into the Nol-Tec blender design, that make it unique compared to other pneumatic blender designs.

Learn More

What Can We Do For You?

Contact us to speak with a member of our sales team about a specific system or our capabilities.

Get in touch